Enhanced coalbed methane

The Ins and outs of coalbed storage.

In addition to removing CO2 from the Earth's atmosphere, there are additional benefits to storing CO2 in coal — and that is the recovery of methane gas. Coal seems absorb methane, which is the principal component of natural gas. And because many homes and companies use natural gas for cooking and heating, it is a prized resource, accounting for about 24% of total U.S. energy consumption. When carbon dioxide is injected into coal, it replaces the methane absorbed within the coal's internal surface, allowing methane to be harvested for energy use. Because coalbeds absorb approximately twice the amount of CO2 than natural gas, coalbeds provide an excellent choice for geological carbon sequestration.

A whole lot of coal going on.

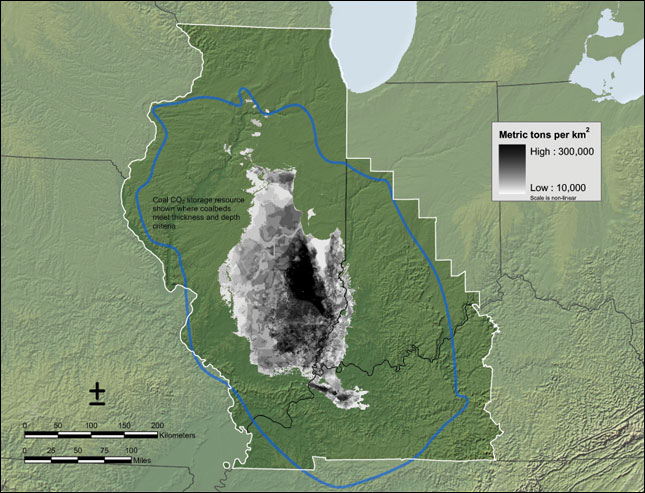

The Illinois Basin holds substantial remaining coal resources, totaling 258 billion metric tons (284 billion tons). To get that coal, minors have use a wide range of extraction techniques ranging from surface mining to room-and-pillar and long-wall subsurface methods, with most of their mining activity occurring around the margins of the Basin.

Most of the Basin's remaining coal resources are moderate to high in sulfur content, which has led to a decline in market share as companies have increasingly turned to low-sulfur, western coal from the Powder River Basin. Since 1990, Illinois coal production has declined by half. The opportunity to store CO2 in coal currently considered to be un-minable is based on both technical and economic considerations and could be supported by production of coalbed methane (CH4) displaced from these coals.

How low will we go?

Research is underway to understand the viability of storing CO2 in what is typically defined as un-minable coal. Because modern mining equipment is not currently designed to handle coal seams that are less than 1.1 m (3.5 ft) in thickness, smaller coal seams below 305 m (1,000 ft) offer an ideal target for sequestration. Storing CO2 in these coalbeds does not make the coal un-mineable; it simply means that any CO2 stored in the coal would either be released or stored in another geologic sink when it is eventually mined.

The characteristics of coal.

As part of our research, the key characteristics of seven coals were mapped throughout the Illinois Basin. These characteristics included thickness, depth, elevation, moisture content, ash content, heating value, temperature, and expected reservoir pressure. Most data were available for the Herrin and Springfield coals, the major coal seams in the Basin. Gas contents for Illinois Basin coals are in the range of 3.12 to 4.68 m3/metric ton (100 to 150 standard cubic feet [scf]/ton) for the better samples, while CO2 adsorption capacity can range from 14.1 to 21.9 m3/metric ton (450 to 700 scf/ton) at 2,068 kPa (300 psi). Using a GIS-based volumetric methodology, the latest storage efficiency factors yield a total storage resource estimate of 1.6 to 3.2 billion metric tons (1.8 to 3.5 billion tons) for the Illinois Basin.

| State | CO2 Storage Resource*

(million metric tons) | Estimated ECBM**

(billion scf) |

| Illinois | 1,470 to 2,900 | 2,700 to 9,800 |

| Indiana | 86 to 170 | 150 to 600 |

| Kentucky | 68 to 134 | 130 to 470 |

| Total | 1.6 to 3.2 billion metric tons | 3.0 to 10.9 trillion scf |

* Using storage efficiency (E) factors of 39% and 77%, respectively.

**ECBM was estimated based on a methane recovery factor that was applied to the original gas-in-place volume per coal seam for un-minable coal areas as described above.

For additional information and more detail see:

World Resources Institute

National Energy Technology Laboratory (NETL)